ROADSIDE REVEGETATION

An Integrated Approach to Establishing Native Plants and Pollinator Habitat

5.1 Introduction

A successful revegetation project requires not only good planning but effective implementation of the plan. The Initiation Phase of this report (Chapter 2) described the organizations, decision processes, and technical concepts involved in beginning a roadside revegetation project. The Planning Phase chapter (Chapter 3) outlined the steps in the revegetation planning process resulting in a revegetation plan. This chapter details how the revegetation plan is translated into action at the project site.

The shift from the planning phase to the implementation phase involves a change in approach, and often, personnel. The planning process tends to be orderly and systematic, with the design team able to take an idealized bird's-eye perspective of how the project might best proceed. In contrast, implementation requires flexibility and adaptability in order to fulfill the objectives of the plan while working with the sometimes-unpredictable nature of construction.

The tasks necessary to successfully implement a revegetation plan are:

- Developing contracts

- Developing an implementation schedule

- Maintaining a materials inventory

- Reviewing plans and coordinating with project engineer

- Assisting in implementing contracts

This chapter provides an overview of the implementation process, providing details on the key factors to consider, including soil and site treatments, obtaining plant materials, installing plant materials, and caring for plants after they have been installed.

5.1.1 Developing Contracts

Revegetation tasks can be performed in-house, by agency personnel, or through contracts, either performed within the scope of road construction contracts or as separate revegetation contracts. The FHWA and most state DOT agencies have developed revegetation contract specifications within their standard specifications for construction of roads and bridges. These specifications are designed, in most cases, to be included directly into a road construction contract or revegetation contract. As a designer, it is important that the language in the contract specification accurately describes both the work to be done and the desired outcome, from a revegetation standpoint. Because every revegetation project is different in scope and environmental setting, it is essential that these factors are conveyed in the specification.

For the Designer

Special Provisions or Supplemental Specifications require agency review and approval and the process may take several months. Identification, development, and submittal of these specifications early in the project will reduce delay of final project review approvals for bidding.

Contract specifications detail the how, not the why. To understand the background for a specification for revegetation, it may be useful to review the implementation guides presented in this chapter that pertain to the specific task or topic. With this information, a special provision or supplemental specification based on standard DOT or other agency specifications can be developed to respond to the specifics of the project and environmental surroundings. It may also be helpful to review contract specification examples developed by other agencies. Some revegetation specifications for the FHWA and several state DOT's can be found in the Native Revegetation Resource Library by selecting "Contract Specifications" under the Report Type search filter.

To evaluate the implementation of contracts, quality assurance standards are defined in the contract specifications. The contractor typically provides monitoring and inspection of these standards to ensure that tasks are carried out as contracted. For example, a hydroseeding contract may have a specification to apply 30 pounds of seeds, 1,000 pounds of wood fiber mulch, and 50 pounds of tackifier per acre. Quality control for this task might be to count the pounds of seeds, wood fiber, and tackifier going into the hydroseeder tank and measure the area to which the mix is applied. This assessment determines if that the rate of materials applied is within quality standards and, if not, alerts the contractor to make appropriate corrections. The written results of these assessments become "as-built" records which can be used by the designer when developing the monitoring report (Section 6.2).

Accurately calculating the contract area is essential in developing contracts. Table 5-1 is an example of how cross sections can be used to determine the contract area. When cross sections are not available, the contract area can be determined from the plan map. In this method, the area is measured and adjustments are made for slope gradient (Table 5-2). A third method is to physically measure the distances in the field.

Table 5-1 | Calculating project area from road plans and cross sections

In this example, cross sections are available for each station. The length of each cross section is measured and recorded in a spreadsheet. The slope length is multiplied by the distance between stations to calculate the area for that station. When all stations areas are calculated, the total contract area is summarized.

Station |

Slope length (m) |

Distance between stations (m) |

Area (m2) |

20+1000 |

3 |

20 |

60 |

20+1020 |

4 |

20 |

80 |

20+1040 |

6 |

20 |

120 |

20+1060 |

7 |

20 |

140 |

20+1080 |

6 |

20 |

120 |

20+1100 |

4 |

20 |

80 |

20+1120 |

2 |

20 |

40 |

Total |

640 |

||

Acres |

0.16 |

||

Table 5-2 | Area computations adjusted for slope gradient

When cross sections are not available, the plan map can be used to calculate area. On steeper terrain, the area may need to be adjusted by slope gradient based on the following factors.

Slope (V:H) |

Increase factor |

Percent of increase |

1:1 |

1.41 |

41% |

1:1.5 |

1.20 |

20% |

1:2 |

1.12 |

12% |

1:2.5 |

1.08 |

8% |

1:3 |

1.05 |

5% |

1:4 |

1.03 |

3% |

1:5 |

1.02 |

2% |

The contract specifies the work to be done by the contractor or agency personnel, with clear definitions of roles and schedules.

In general, a contract outlines the following:

- Supplies/services to be provided

- Scope of work (size, schedule, etc.)

- Project location

- Contractor obligations

- Revegetation specialist obligations

- Delivery details (who, how, when, including timelines and deadlines)

- Quality standards

- Contractor quality assurance plan (to be provided by contractor)

- Revegetation specialist quality assurance plan (to be provided by designer who will be inspecting the contractor's work)

- Price (including bid, unit prices, additive or deductive alternate items)

- Payment method (submission of invoices, approval of work)

- Contractor's designated representative (more efficient to only coordinate with one person)

- Safety plan

- Other terms and conditions (e.g., what to do in the event of changes)

5.1.2 Maintaining Schedules and Materials Inventory

Revegetation contracts can begin up to three years before road construction. For example, it is not uncommon for a seed or plant procurement contract to begin during the planning stage of a road project and span into road construction. In addition, procuring plant materials and implementing mitigating treatments often involve separate schedules with different contractors. To keep these details straight, developing an implementation schedule can be helpful. Timelines are often developed during the planning stages and included in the revegetation plan and these become the basis of an implementation schedule.

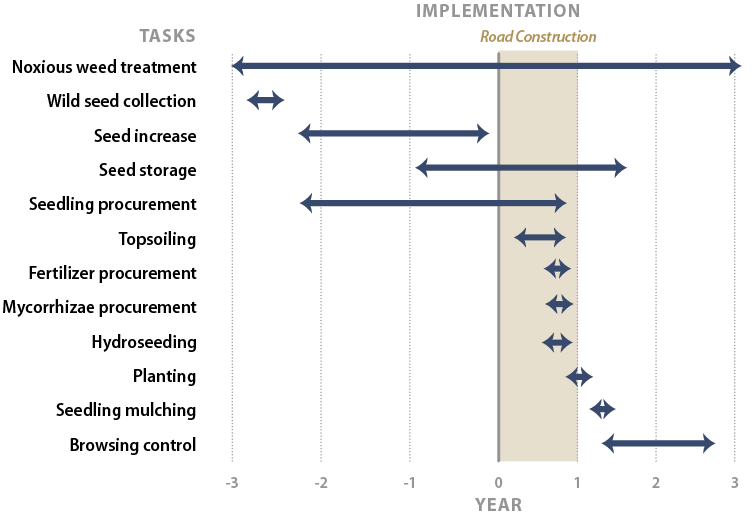

Figure 5-1 | Example implementation schedule

In this implementation schedule overlapping tasks, some requiring different contractors, are displayed.

Most schedules have interdependent and time-linked tasks. In Figure 5-1, for example, the hydroseeding contract is dependent on the success of the seed increase contract. Before that, the seed increase contract requires wildland seeds to be collected by agency personnel or contractors. The success of the hydroseeding contract rests on the successful execution of two tasks that begin years before the actual seeding.

When creating schedules, it is important to incorporate additional time needed to issue contracts. This is especially crucial when ordering plant materials, which will require several years for production.

Material quantities for revegetation tasks change through the life of a road project. For example, a nursery may have succeeded in growing more seedlings for certain species, while producing less of others (due to poor germination, frosts, insects, disease, or other events). For plant material contracts, it is important to stay in touch with the growers to determine if there are any changes to the inventories, and make adjustments to the inventory as needed. Other material quantities that can change are topsoil and shredded wood for mulch.

5.1.3 Coordinating with Construction Engineer

For some road projects, one engineer will oversee the project from inception through its completion. For more complex projects however, the design engineer may hand off the project to a construction engineer member of the project team or from the DOT or agency client to implement. The design engineer, in this case, ensures that tasks outlined in the revegetation plan are designed into the construction documents: plans, specifications, contracts, schedules, materials lists, and coordinated with erosion control plans. The construction engineer implements the road plan with guidance from the design team. Complex revegetation designs, such as vegetated retaining walls, planting pockets, and other biotechnical engineering structures, may require more involvement from the design team.

Before construction begins, a meeting is often scheduled with the construction engineer, road building contractor, and revegetation design team to discuss the revegetation plan. This meeting covers revegetation objectives and outlines the revegetation tasks that need to be coordinated with road construction activities. The construction engineer is made aware of the revegetation treatments and how they are to be implemented. After the initial meeting, the revegetation designer may keep in contact with the construction engineer to help implement the contract specifications. Timely field visits by the designer will help overcome difficulties in integrating revegetation treatments into construction design and schedule.

5.1.4 Implementation Guides

Implementation guides are presented in this chapter as background for developing contracts or procedures for revegetation tasks.

The following implementation guides are grouped into four subject areas:

- Section 5.2 Soil and Site Treatment

- Section 5.3 Obtaining Plant Materials

- Section 5.4 Installing Plant Materials

- Section 5.5 Post-Installation Care of Plant Materials

The eight guides in Section 5.2 explain how to improve site and soil conditions prior to the installation of plant materials. These guides cover the mitigating measures most often referenced in Section 3.8.

Section 5.3 includes six implementation guides that pertain to collecting and propagating plant materials. These guides describe how to take the species lists developed in Section 3.13, and obtain the desired species in the wild as seed, cuttings, or seedlings. These guides also cover how to increase gathered wild collections at nurseries to ensure that the revegetation project has sufficient quantities of plant materials.

Once plant materials are obtained from the wild or from nurseries, they are installed on the project site. The four guides in Section 5.4 cover the techniques for sowing seed, installing cuttings, and planting seedlings. They also cover how to determine the quality of the plant materials and how to care for them during storage and transportation.

Section 5.5 outlines those practices that occur after the installation of plant materials. These practices help ensure that plants will become established. Practices include protecting seedlings from animal browsing, installing shade cards, irrigating, and installing tree shelters.

Other sources for implementation guides can be found in the Native Revegetation Resource Library by selecting "Implementation Guides" under the Report Type search filter.